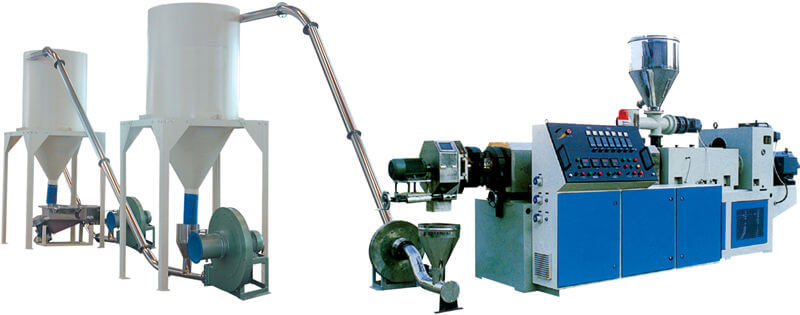

PVC Pelletizing Line

Case study of 80/156 UPVC pelletizing line

Pelletizing extruder for customized solutions

JINZE PVC pelletizing line adopts counter-rotating twin-screw extruders with output up to

800kg/h. The screw design can be customized according to your PVC formulations. You can

get wide output range by choosing from 51/105 to 92/188 conical twin-screw extruders. A broad

variety of PVC formulations can be processed by customized screw design. We also help to offer

suitable downstream equipments such as cutting die head, cooling devices and storage silos.

Here is a case study of 80/156 UPVC compounding extrusion pelletizing line.

1.80/156 counter-rotating conical-twin screw extruder

A 80/156 conical twin screw and barrel

400 kg/h screw rotation speed: 1~26r/min

Screw barrel material: 38CrMoAlA

Nitride and Bimetallic treatment

Hardness after nitride: >HV900

Nitride depth: 0.5mm-0.8mm

Screw cooling method: Circulation through water recycling system

Heating zone: 4 zones with total power 33kw

Cooling fans power: 3 sets of cooling fans, 550w each fan

B Feeding System

Stainless steel hopper

0.75kw twin screw feeding system

Controlled by ABB converter

C Gearbox

Brand: DELING

Vertical Type

Adopting German technology, with a long lasting life, low noise and low heating

D Main motor system

AC motor (SIEMENSE)

Main motor power: 55kw, 380V, 50Hz

Main motor convertor: ABB

E Electric control system

Optimized designed electric controlling cabinet with alarm system

Temperature controller:

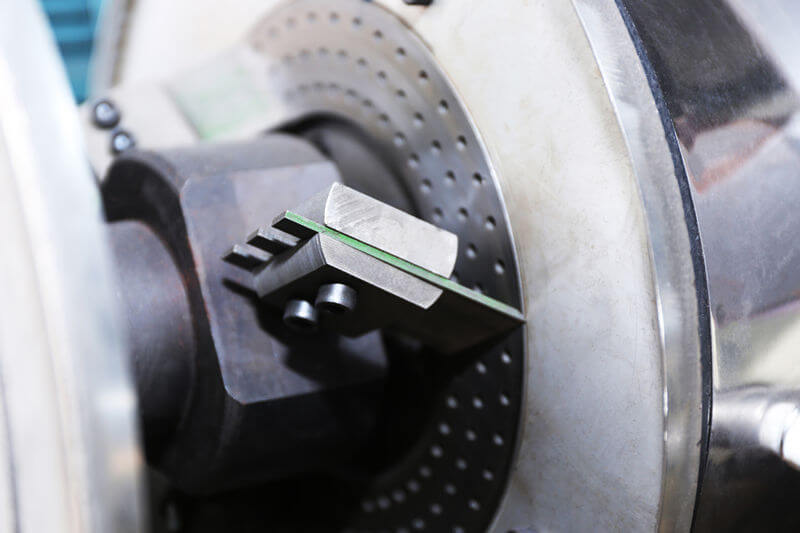

F Hot Cutting Pelletizing Die Head

One set with two pieces of net plates

Diameter of net holes: 3.8mm, 4.2mm

Meet the demands of different pellet size

2.Three-layer wind cooling auxiliary(with vibration)

A Silo

Dia1050mm*2000mm (storage silo: 2Ton)

Dia600mm*1200mm

Dia400mm*800mm (connected with vibration)

B Pipe size: 3 pieces of stainless connecting pipeline

C Blowers: 3 blowers

D Vibration: Screen diameter: 1mm; 6mm

Two cooling fans on the downside of the screen

Vibration is designed closed and covered by stainless steel

Twin screw barrel

Twin screw barrel