Email:info@jinzeplastic.com

Mobile/WhatsApp:0086-13818551740

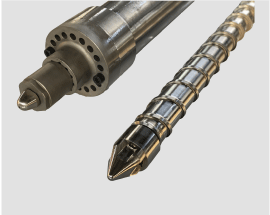

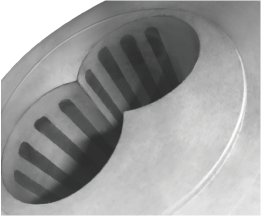

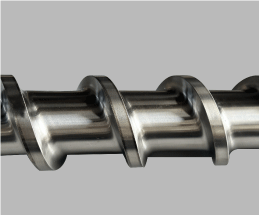

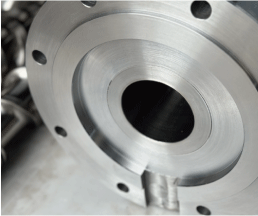

and Injection Moulding Screw Barrel

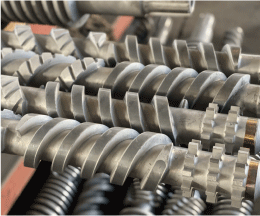

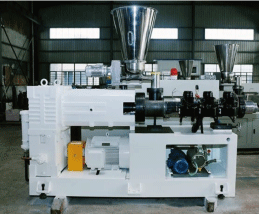

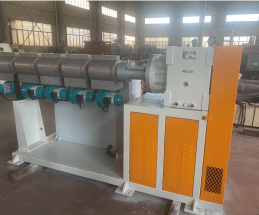

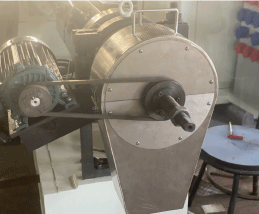

Take a video tour through our workshop to see

how screws and barrels are manufactured from

raw steel material to heat treatment and final

polish.

From raw steel material to a completed set of

screw barrel, there are several working procedures.

The normal production period of screw

barrel is from 20-40 days.

Expertise

More than 20 years experience in extruder screw barrel designing and manufacturing can ensure the performance and quality of your extrusion process.

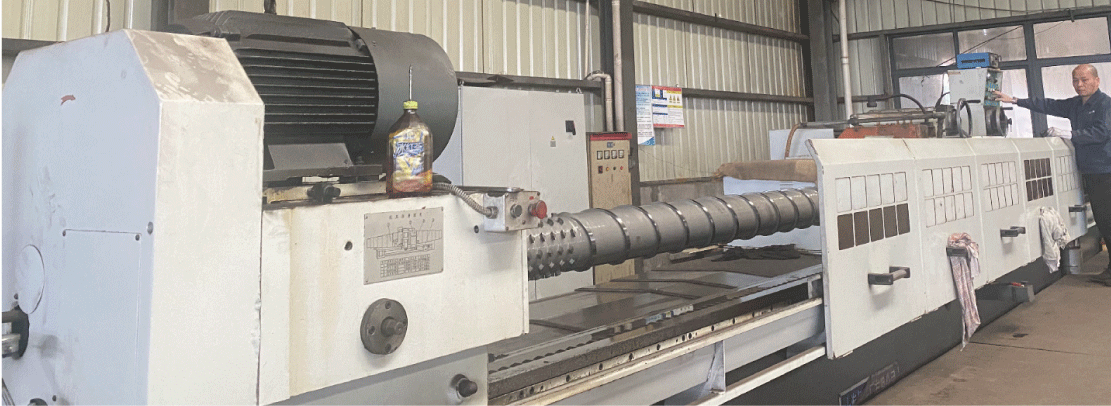

Facilities

Well equipped with facilities such as 8-me-tel CNC lathe, milling machine with working diameter 300mm, Grinding machine with working length 8 meters and boring machine with boring depth 6 meters can meet your customization needs.

The products will be packaged by PE winding

film and plywood case when delivered by

Less than Container Load.

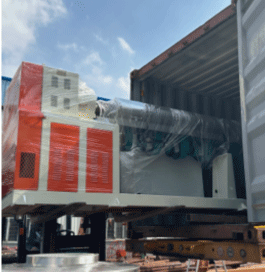

The machines will be packaged by PE winding

film and fixed when delivered by full container

loading.

You will receive the goods perfectly without

damage.

Replace Your Extruder Screw Barrel

Tell us the screw model you need and the polymer you are processing. Your extruder brand name and your final products.

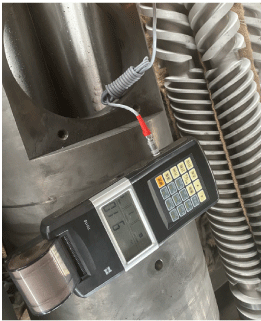

Problem shooting, redesigning and drawing confirmation to ensure the screw barrel successful installation and extrusion performance.

Production, quality inspection, package and quick delivery. Consulting during your installation ond testing processes.